Following the construction of the new East Span of the San Francisco-Oakland Bay Bridge in 2013, phase 1 of the dismantling of the old East Span included a requirement for the piece by piece removal of the cantilever truss main span.

Due to the complexity of the structure, Foothills Bridge Co. (the contractor’s engineer of record for phase 1) used LUSAS Bridge analysis software to model and develop a fully engineered dismantling sequence on behalf of its clients Silverado Contractors, Inc. and California Engineering Contractors, Inc. for the bridge owner, Caltrans.

Bridge Owner: Caltrans

Contractor: Silverado Contractors, Inc.

Contractor: California Engineering Contractors, Inc.

Structural Engineer: Foothills Bridge Co.

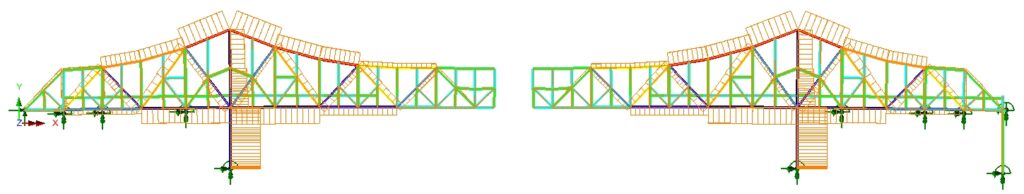

Location of temporary towers and temporary truss members

Axial forces in truss members after initial dismantling at midspan.

Animation of axial forces during erection, in-service alterations, and dismantling.

Animation of axial forces in members during dismantling

The proposed dismantling sequence approximately reversed the sequence used to construct the bridge. Bridge owner, Caltrans, provided a detailed description of bridge erection procedures so that the subtleties of the bridge erection could be modelled and accounted for in the dismantling procedure.

Foothills Bridge Co. used a single LUSAS model to model the entire dismantling sequence of the East Main Span of the San Francisco-Oakland Bay Bridge. The model incorporated equipment and environmental loads (in addition to dead load), and determined existing truss member forces, temporary truss member design forces, temporary tower loads, and temporary tower jacking forces.

This procedure of severing the main span became known to the engineers as “The cut”. Nathan Miller, Bridge Engineer at Foothills Bridge Co. explains: “Before this could be done, the upper chord at each end of the suspended span needed to be re-engaged to convert the suspended span into extensions of the cantilever, and then be jacked to relieve the forces in the suspended span. This would then allow the bridge to be cut at midspan without a large release of energy and minimal bridge deflections. By using LUSAS to model this sequence we could provide the contractor with the required jacking forces and expected bridge displacements.”

Forces and bridge displacements were monitored by the contractor the throughout the dismantling sequence and these field measurements were found to be in compliance with those predicted by the LUSAS model, verifying the bridge was behaving as expected, and providing confidence to all during the dismantling process.

LUSAS

Forge House

66 High Street

Kingston upon Thames

Surrey

KT1 1HN

United Kingdom

We only send occasional emails. Sign-up and stay up-to-date with the latest developments in the world of LUSAS..

LUSAS online sales Dismiss