LUSAS Consultancy Services has extensive experience in carrying out a wide range of analyses for large storage LNG tanks. Over the years its specialist engineers have assisted Korea Gas Technology Corporation (KOGAS-Tech) on various projects and analyses including, more recently, the seismic isolation analysis of a 180,000m3 full-containment tank for the Costa Norte LNG Terminal project in Panama.

On completion in 2018, it became the first LNG reception terminal in Central America.

Installation of base isolation system (Image: AES Colon)

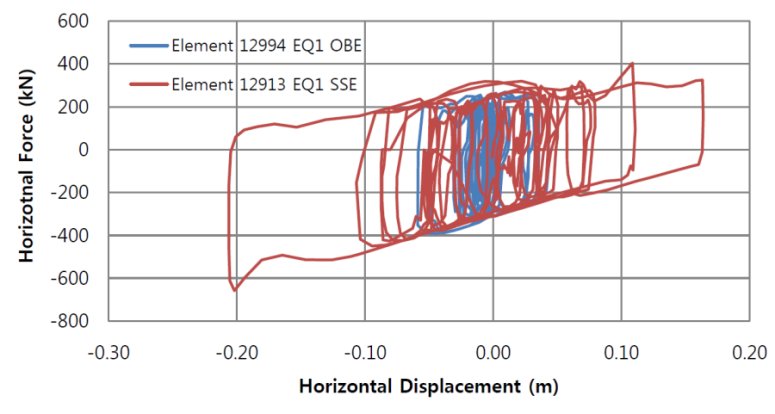

Isolator force-displacement curve

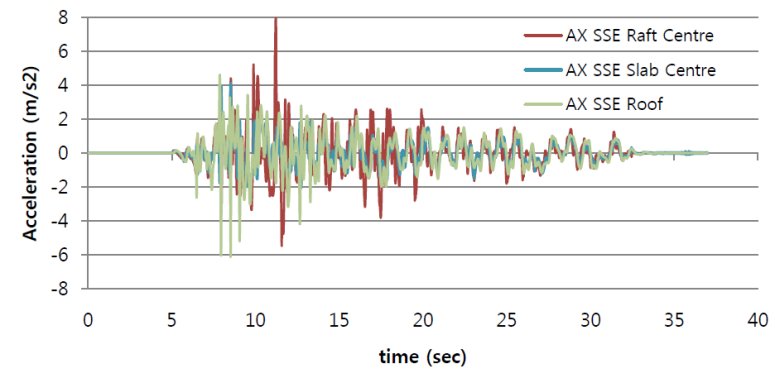

Acceleration-time reponse in horizontal direction

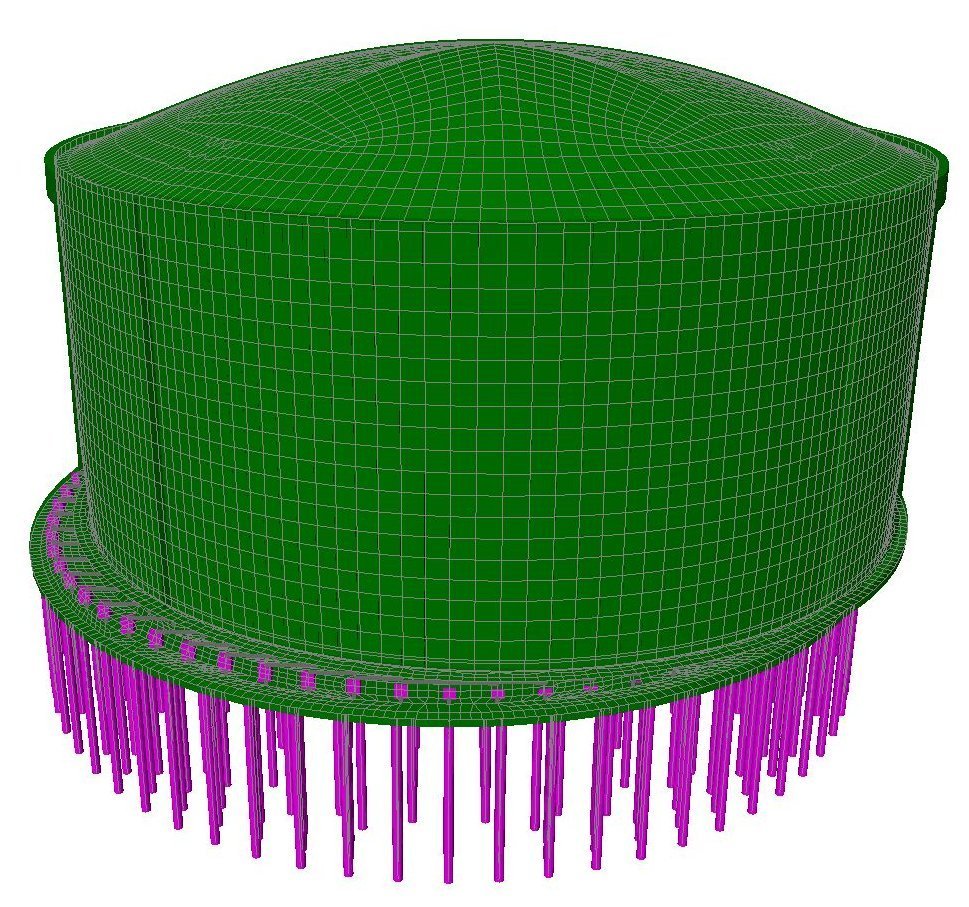

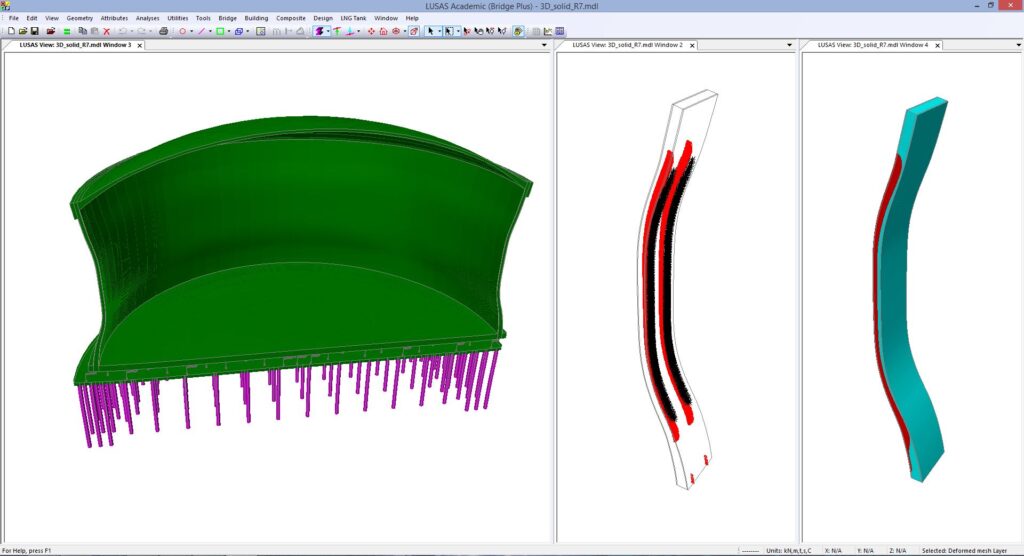

Shell model deformation.

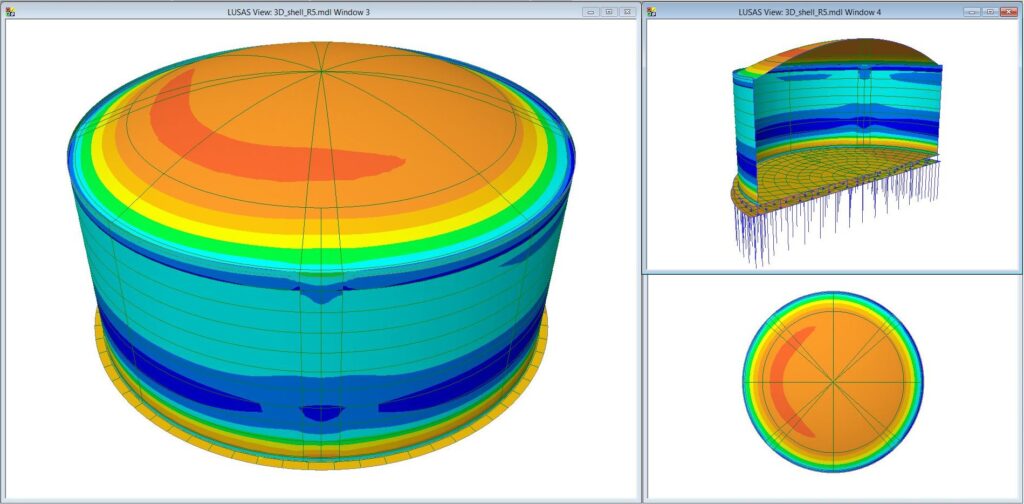

Hoop axial forces in shell model

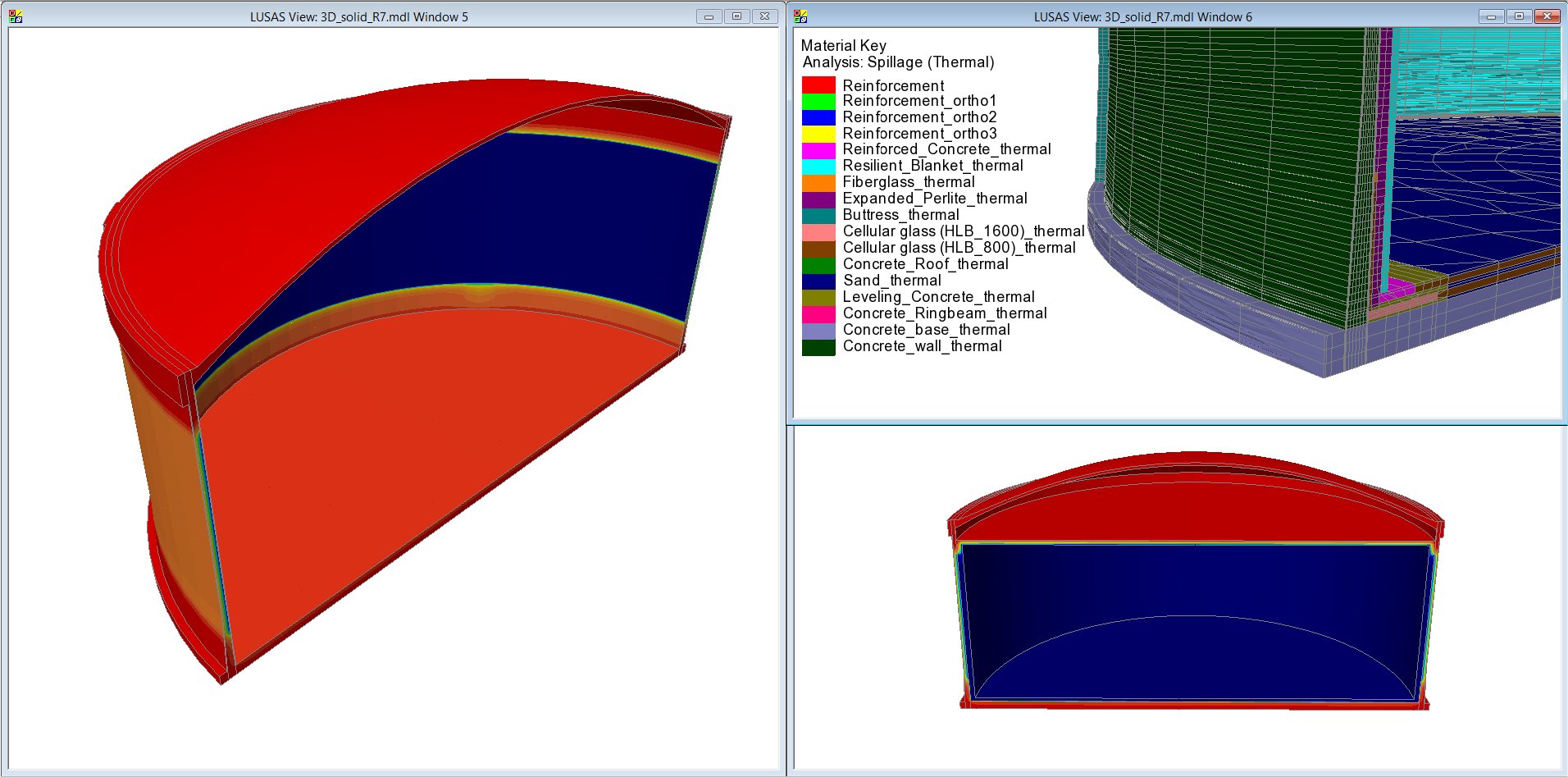

Spillage temperature results and tank material modelling

Piecewise linear joint materials varying with depth were used in LUSAS to simulate the nonlinear response of soil, including lateral bearing capacity, skin friction and end bearing resistance.

Liquefaction potential, cyclic loading, group effects and soil damping were considered in the computation of the axial and lateral stiffness of the soil support.

Triple friction pendulum bearing (TFPB) isolators were modelled in LUSAS using specialised joint materials which included hysteretic damping and the variation of friction with sliding velocity and normal pressure. As friction properties are variable with time and also axial force, lower and upper bound properties were used for the empty and full tank cases.

Under peak conditions, the base-isolation was able to provide an overall effective damping of up to 33%, with peak displacements of around 200mm, well within the 605mm bearing capacity.

Lumped mass modelling was used for fluid/structure interaction of the LNG and for soil/structure interaction of the pile arrangement. The nonlinear hysteretic behaviour of the isolation system required a detailed dynamic analysis. Using nonlinear transient dynamic analyses in LUSAS, time-history responses were obtained under simultaneous horizontal and vertical ground motion.

A 3D solid model that included a state-of-the-art nonlinear concrete material was developed to carry out a semi-coupled steady state thermal analysis to assess the effects of the spillage on the tank wall. Similarly, as for the shell model, peak hydrodynamic pressures were subsequently applied to the solid model and the liquid tightness and collapse prevention of the concrete tank were assessed.

Spillage temperature results and tank material modelling

LUSAS

Forge House

66 High Street

Kingston upon Thames

Surrey

KT1 1HN

United Kingdom

We only send occasional emails. Sign-up and stay up-to-date with the latest developments in the world of LUSAS..

LUSAS online sales Dismiss