The Emirates Air Line is the UK’s first urban cable car and one of the most exciting additions to London’s infrastructure in recent history. Completed in June 2012, after a rapid 15 month design and construction period, the landmark project stretches 1.1km across the River Thames, providing a direct link between the O2 Arena and ExCel Exhibition Centre. An integral part of former Mayor of London Boris Johnson’s vision to transform East London, this innovative mode of transport offers it’s passengers a memorable experience and stands as a vibrant catalyst for further regeneration of the area.

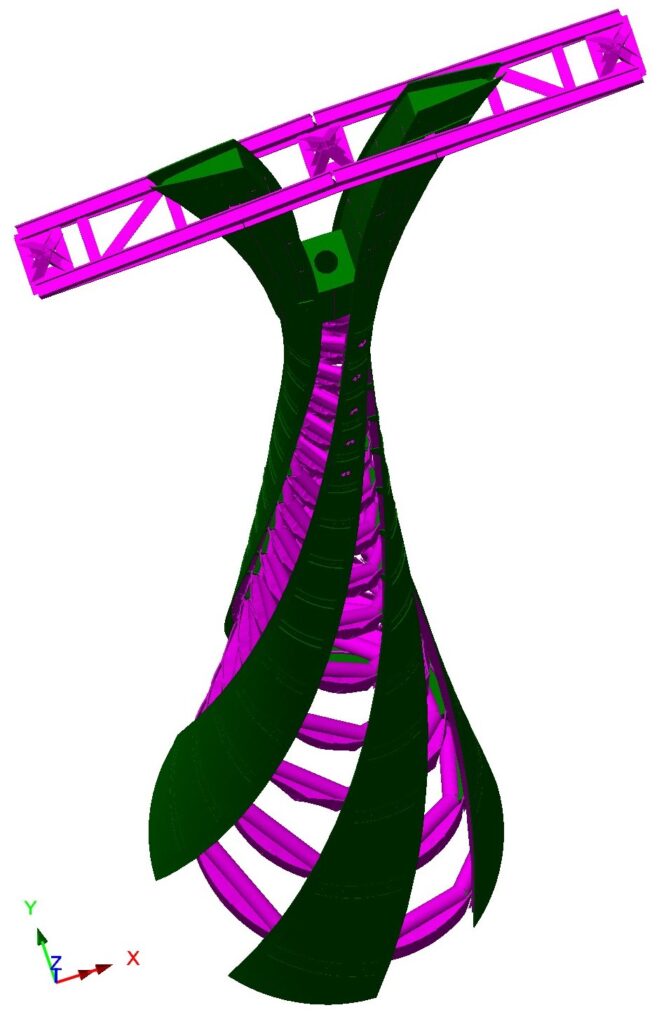

Rising high above the Thames, spiralling steel ribbons form the Air Line’s sculpted towers, held in place by helical braces that corkscrew up the inside of each structure. In a bold architectural statement, engineering and aesthetics meet with perfect harmony to convey a sense of lightness and movement against the backdrop of London’s ever-evolving skyline.

Client: Transport for London

Structural Engineer: Buro Happold

Structural Engineer: AECOM

Principal Contractor: Mace

The Design and Build contract was awarded by Transport for London to main contractor Mace. Structural design was shared between Buro Happold, who were responsible for the design of the three main towers, and URS (now AECOM), who designed the stations and adjacent compression towers. AECOM also carried out a Category 3 check of the design of the main towers using LUSAS consultancy services to assist with this task.

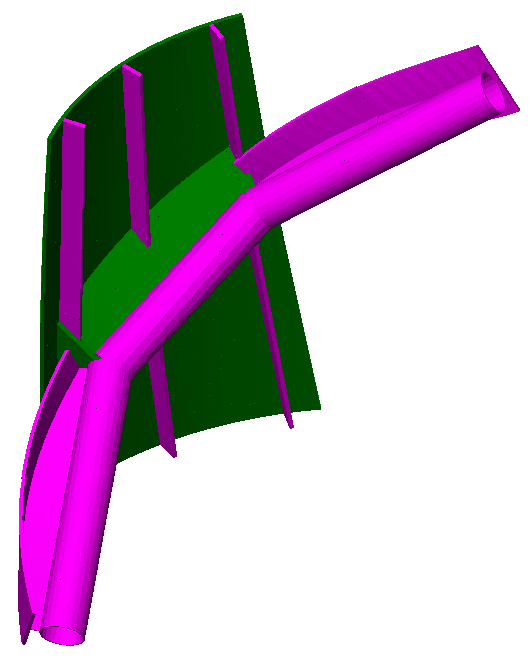

Beam and shell model of connection

Tower modelling

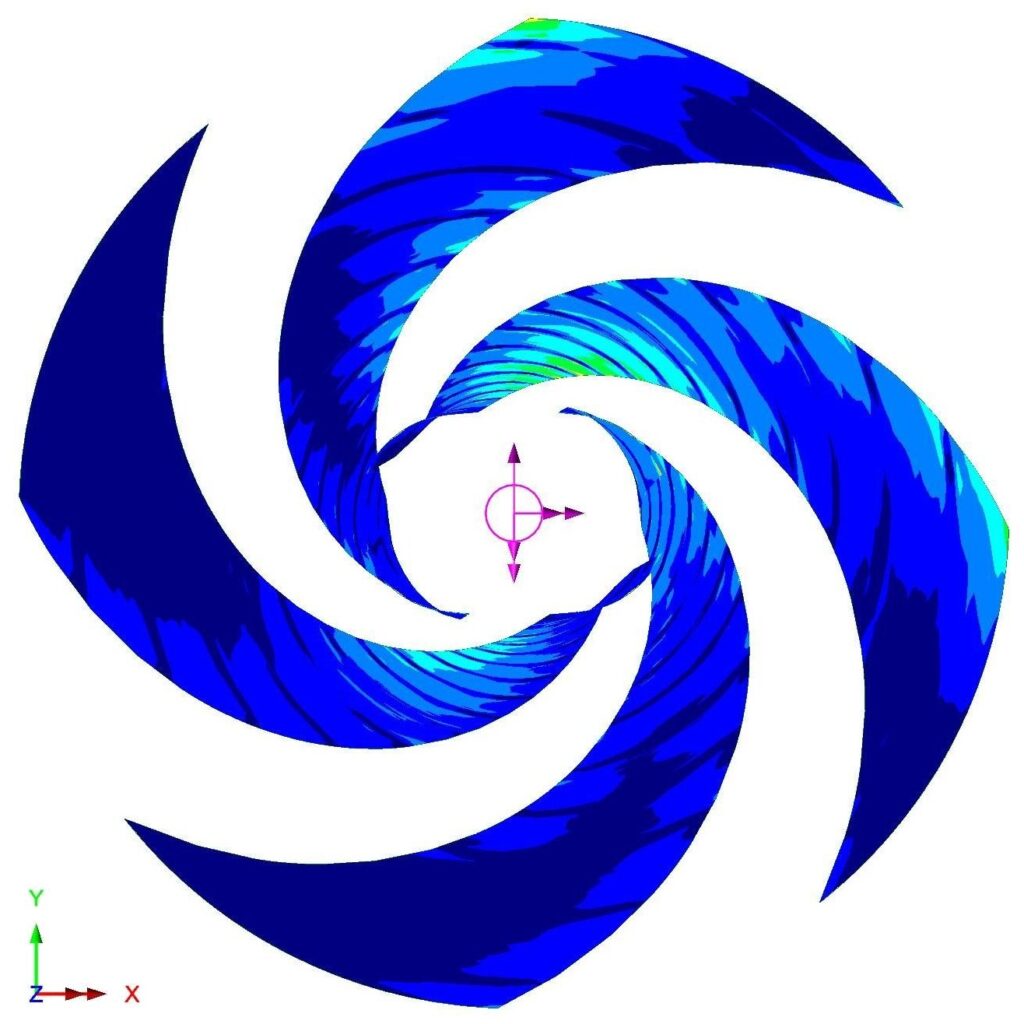

Stress in ribbons from full spectrum envelope

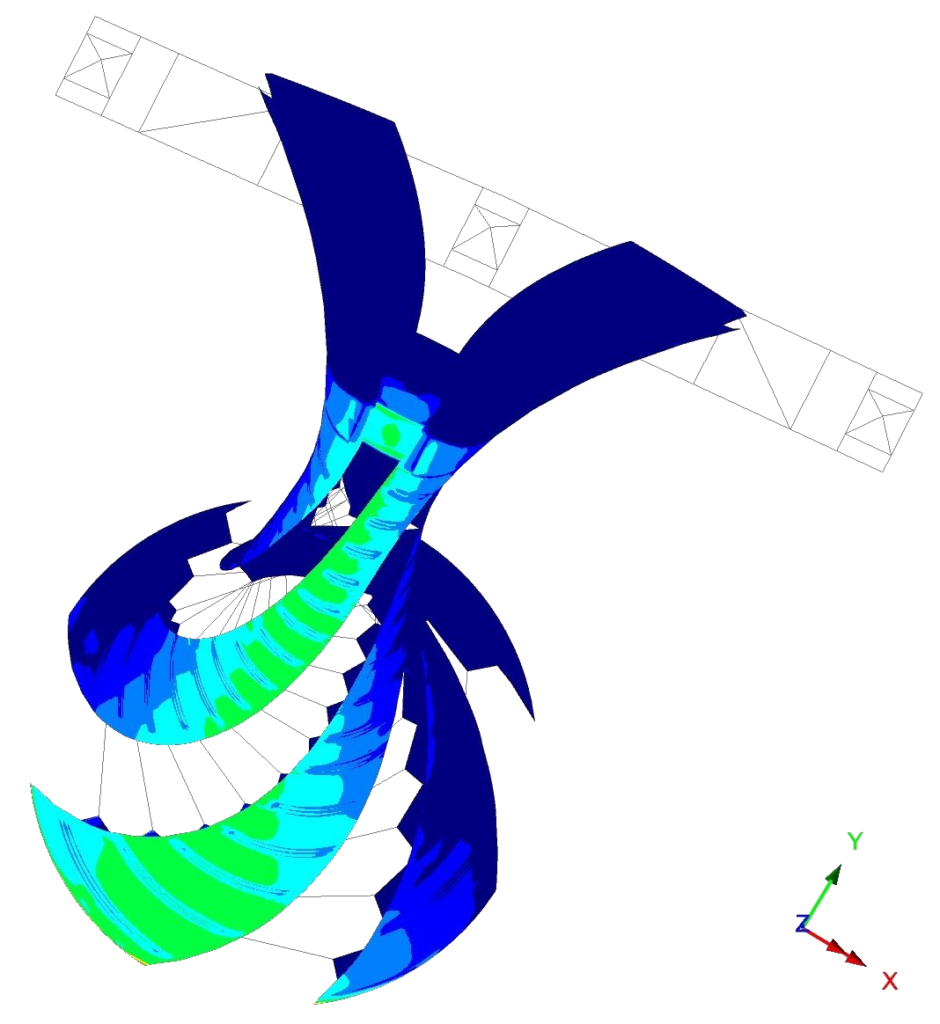

Thermal strain on ribbons

Through collaboration with LUSAS Technical Services, and their extra know-how using the LUSAS Programmable Interface, AECOM were able to generate models, loading patterns and results at the rate which was demanded by the short timescale of the project.

Potentially prone to movement and resonance caused by the wind, analysis of the distinctive spiralling design of the pylons was critical for safety and comfort as passengers ‘fly’ some 85m above the river.

It was the connections between the architectural ribbons and the hidden counter-spirals, made of smaller hollow sections, that turned out to be crucial to the behaviour of the towers. This could only be understood with detailed shell element models, whereas the design checks to the Eurocode required simplified beam element results. LUSAS provided the tools to correlate these two, offering the best of both worlds.

LUSAS

Forge House

66 High Street

Kingston upon Thames

Surrey

KT1 1HN

United Kingdom

We only send occasional emails. Sign-up and stay up-to-date with the latest developments in the world of LUSAS..

LUSAS online sales Dismiss