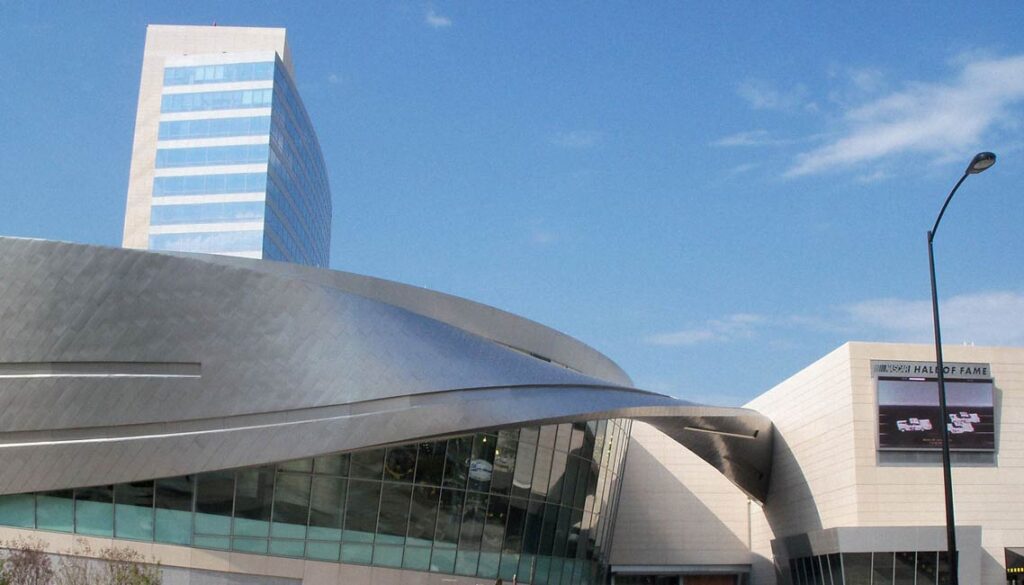

Genesis Structures used LUSAS software to assist with the design of a complex structural ‘ribbon’ that wraps around the roof of US National Association for Stock Car Auto Racing (NASCAR) Hall of Fame building.

The flowing ‘ribbon’ begins as a curved sloping exterior wall on one side of the building before twisting in a free span over the main entrance to form a signature canopy, and then reappears to the rear to fully surround the building. Clad in stainless steel, its shape is intended to symbolise the banked tracks of the racing circuits and the long, thin recesses in its skin suggest the blur of cars racing at speed.

Client: City of Charlotte

Contractor: Zahner

Structural engineer: Genesis Structures

Architect: Pei Cobb Freed & Partners

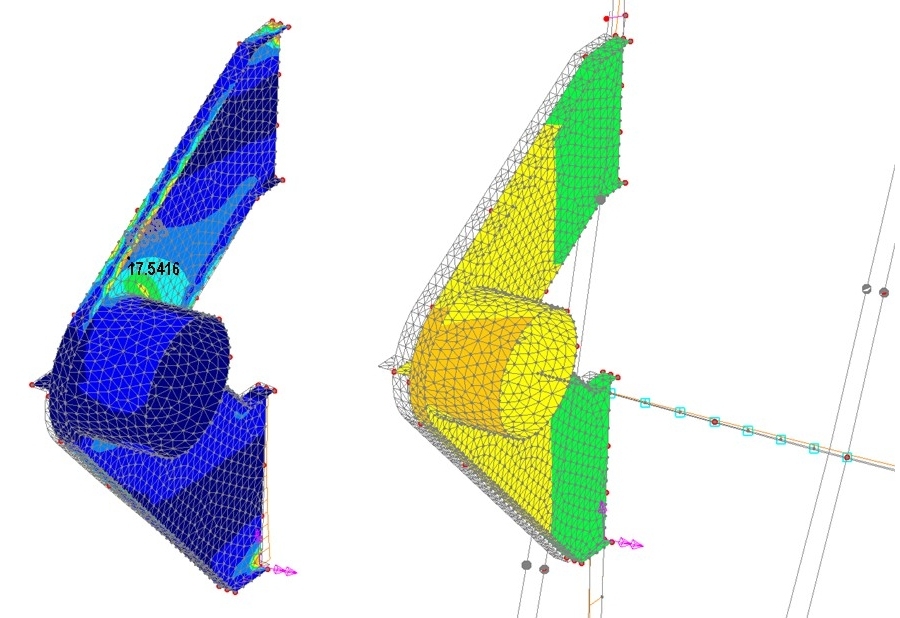

LUSAS model of supporting wall and ribbon structure

Stress and temperature loading effects on steel pipe support

Lifting of the mobius ribbon support pipe..

Mobius pipe with aluminium panels fitted

Zahner of Kansas City, Missouri, was awarded the construction contract for the exterior ribbon feature of the building. Zahner employed Genesis Structures for its structural engineering expertise in this type of work.

The wall system that makes up the ribbon is constructed from aluminum panels that are approximately 8 foot in width. Wall heights vary with the tallest being in the region of 45 feet. Using a proprietary aluminum extrusion system, developed by Zahner, Genesis optimized the design and fabrication of the curved planar surface by employing a cold-formed aluminum decking system, supported by horizontal built-up, curved ribs to form the surface of the dynamic wall. Wall panels were erected on steel spandrel beams designed by the building structural engineer, LERA. Specially designed anchors allowed for small amounts of vertical field adjustment to ensure perfect alignment.

To analyse the mobius ribbon structure Genesis built a detailed LUSAS model of the building framing system to ensure the correct structural response was being captured. Because of the unique geometry of the supporting framing system, a detailed local model of the steel mobius support was also created. Stress and temperature effects were investigated and results obtained were provided to the building engineer of record to confirm their own design assumptions and verify that the correct structural response was being captured

LUSAS

Forge House

66 High Street

Kingston upon Thames

Surrey

KT1 1HN

United Kingdom

We only send occasional emails. Sign-up and stay up-to-date with the latest developments in the world of LUSAS..

LUSAS online sales Dismiss