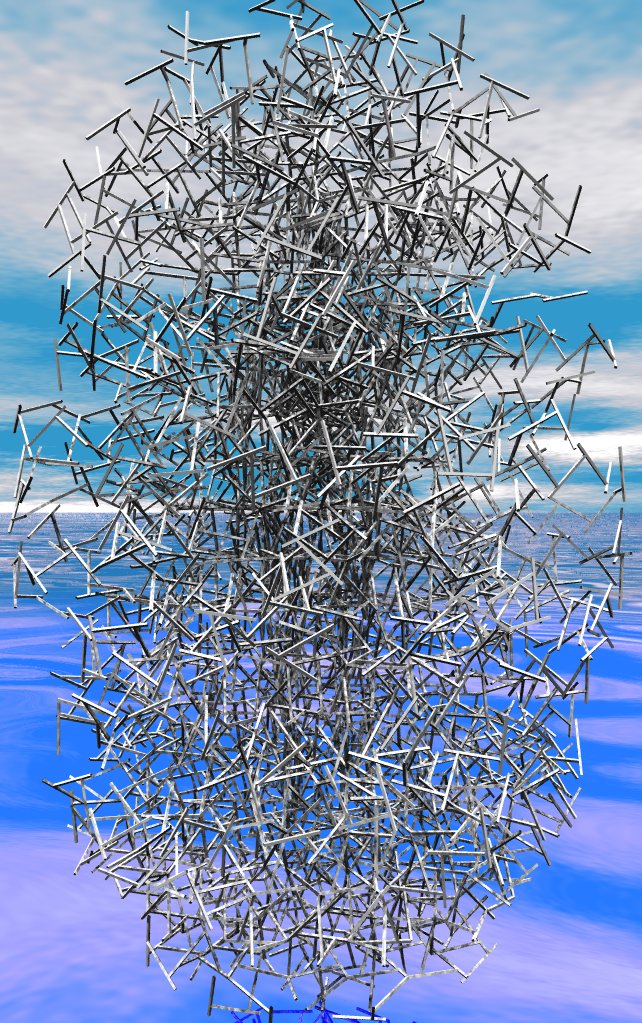

“Quantum Cloud” is an elliptical cloud sculpture which stands adjacent to the O2 arena in London, UK. The work of “Angel of the North” sculptor, Sir Antony Gormley, it is formed from lengths of randomly oriented steel sections which diffuse at the edges and condense into a 20 metre high human body form at the centre. The engineering design team of Elliott Wood Partnership and LUSAS consultancy services worked closely with Gormley to develop the full scale realisation of his vision for the client, the New Millennium Experience Company. Fractal growth software written by LUSAS helped develop the structural form, and modelling and analysis with LUSAS finite element software ensured the unique structure was fit for purpose.

Client: New Millennium Experience Company

Artist: Sir Anthony Gormley

Engineer: Elliot Wood Partnership

Engineering Consultancy: LUSAS

Contractor: Tube workers (Structures) Ltd.

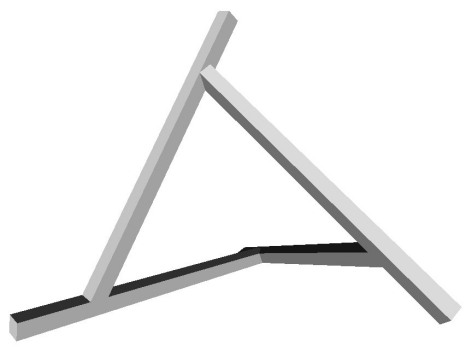

Tetrahedral steel unit

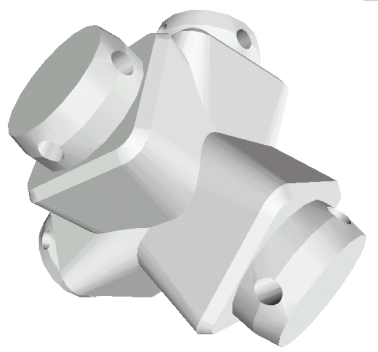

Casting

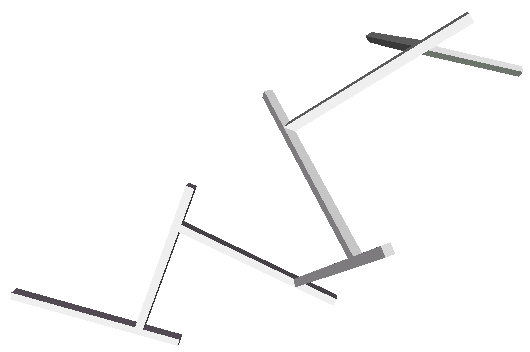

Tendril

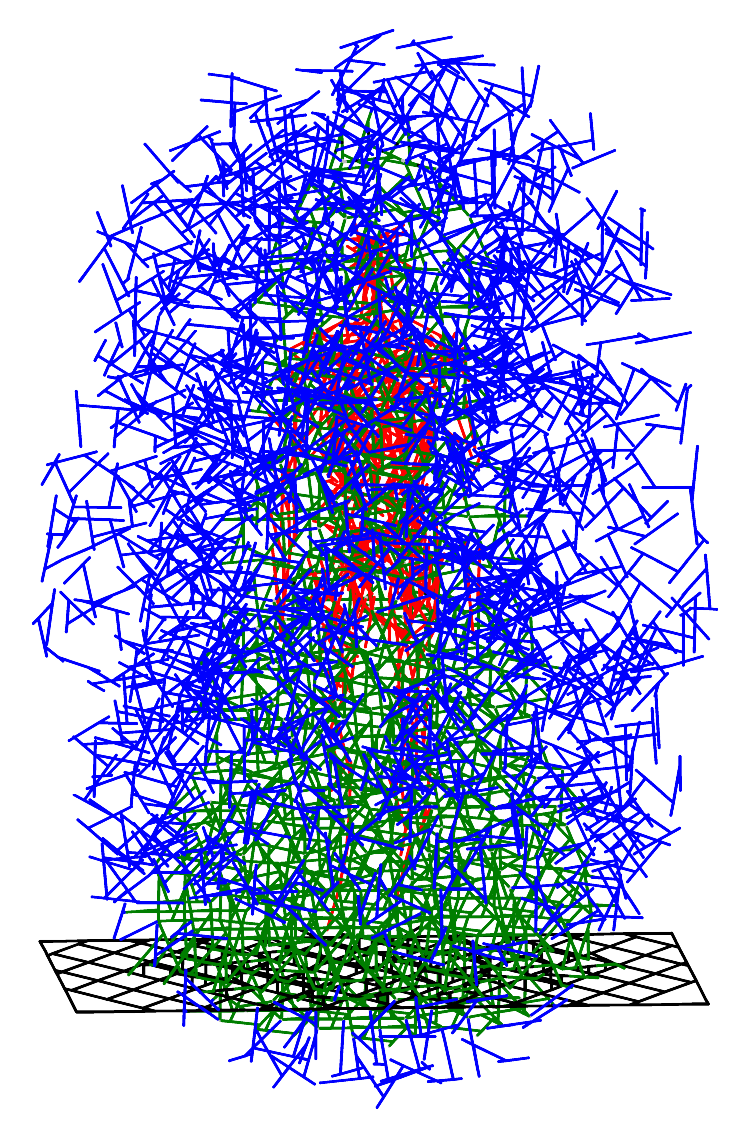

VRML model

LUSAS model

(showing lattice, core, body form and tendril regions)

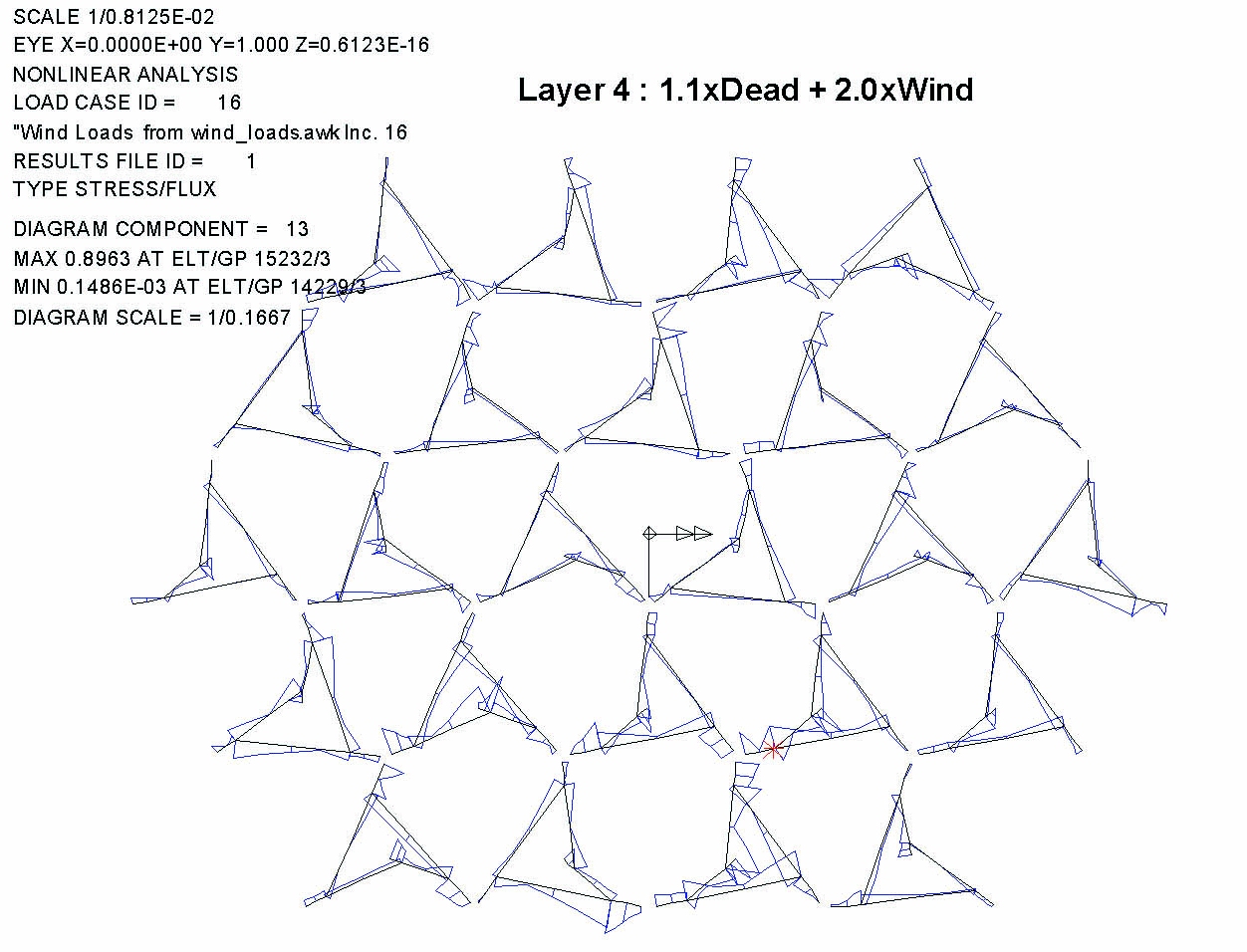

The sculpture, whilst visually random in nature, in fact consists of three distinct regions. A central structural core of 1.65m sided, tetrahedral steel units provides support for an outer steel tendril region that forms the cloud shape, and also provides the restraint for an inner body form structure. The structural core rests on a lattice of beams that span between the four supporting caissons.

LUSAS wrote custom software to generate the 17 randomly oriented layers of tetrahedral units that occupy the width and height of supporting structural core. An additional layer beneath the supporting steel lattice provides fixity for the tendrils in this region. This software also generated LUSAS modelling and analysis data files, a DXF file for use in creating detailed member design drawings and an input file used to create each 3D casting model.

Ray traced images and VRML models of potential structural forms, created by using the LUSAS Programmable Interface (LPI), allowed the sculptor to examine the structural options from every conceivable angle.

The use of innovative engineering ideas from all members of the project team, LUSAS Engineering Consultancy Services’ skill in producing complex custom software to grow and develop potential structural forms, and the use of LUSAS analysis software to model and prove the structural integrity of the sculpture, ensured that the design and analysis of a complex structure was completed to the sculptor’s satisfaction in a very tight timescale.

LUSAS

Forge House

66 High Street

Kingston upon Thames

Surrey

KT1 1HN

United Kingdom

We only send occasional emails. Sign-up and stay up-to-date with the latest developments in the world of LUSAS..

LUSAS online sales Dismiss