Flint and Neill Ltd (now COWI) was appointed by principal contractor Balfour Beatty to provide erection engineering services for the deconstruction of the original roof of the London Olympic Stadium and subsequent construction of a new long-span replacement roof for what is now called the London Stadium. This work was required as part of transformation works carried out on behalf of the London Legacy Development Corporation.

LUSAS was subcontracted by COWI to perform independent checking of the various deconstruction and construction stages involved, and confirmed the adequacy of the structural members which formed the permanent works and global stability of the structure under applied loads.

At the time of its construction the replacement roof was believed to be to be the longest cantilevered roof in the world.

Client: Transport for London

Principal Contractor: Balfour Beatty

Structural Engineer: Buro Happold

Erection engineer: COWI

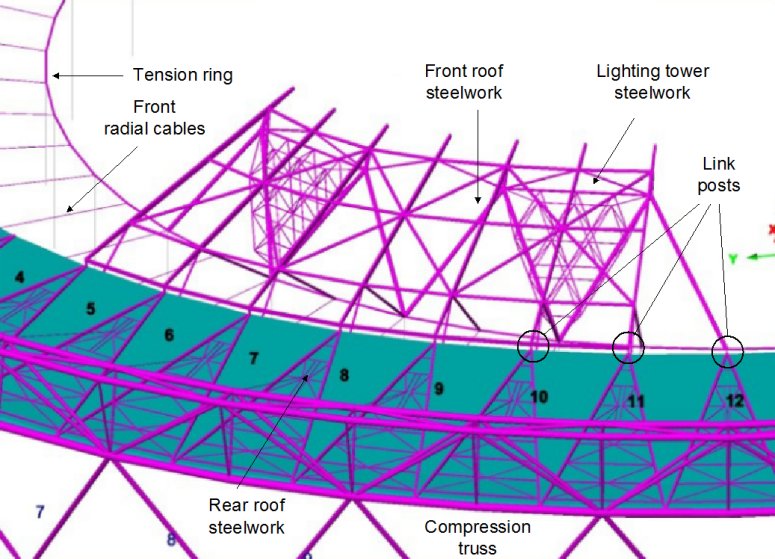

Modelling of rear and front roof erection sequences..

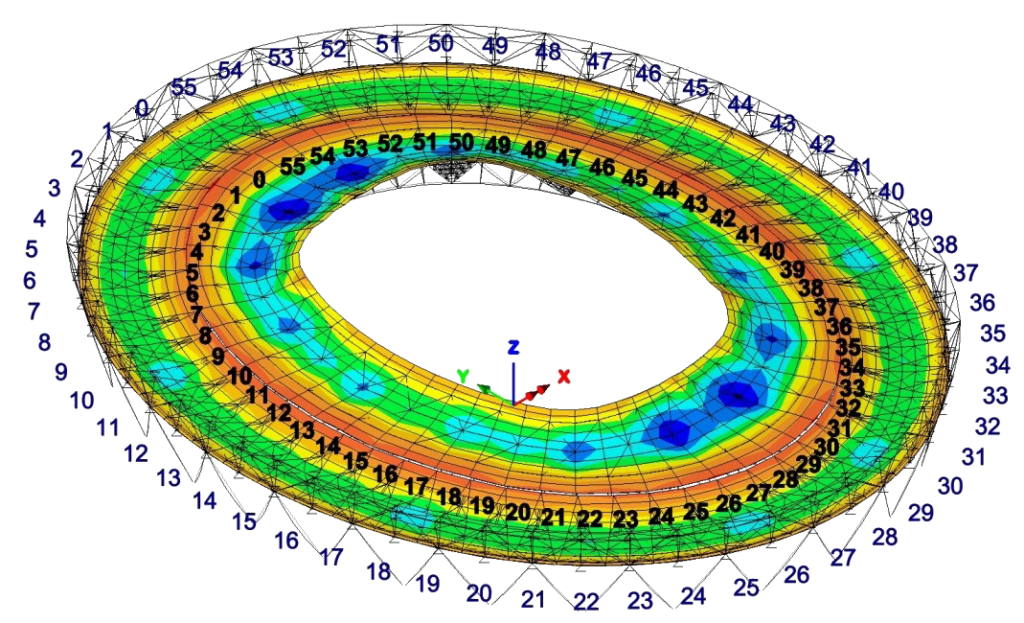

Vertical displacement contours for final roof position (for cladding speed case 1).

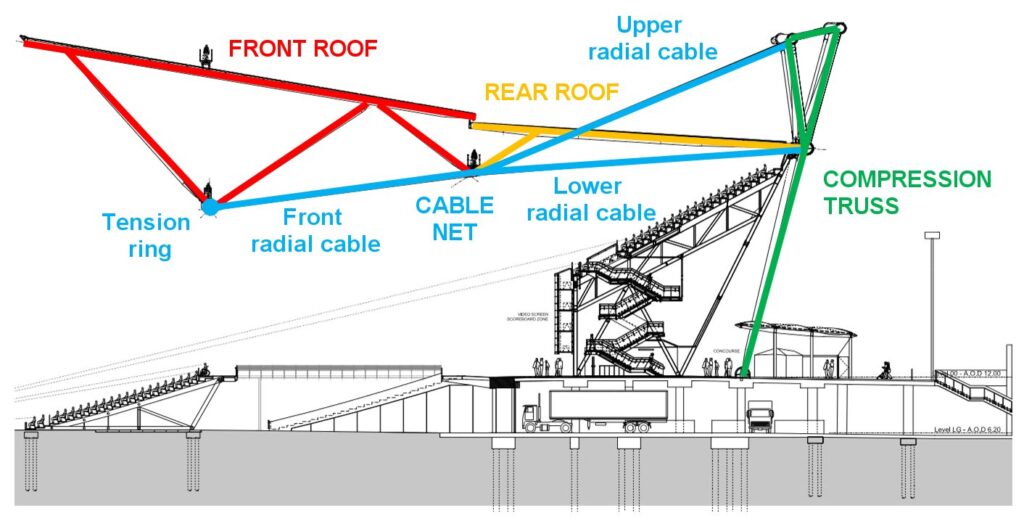

The new roof consists of a primary cable net structure supporting articulated steel trusses which create the upper roof profile and in turn support the roof coverings. The existing compression truss connections and raked V-columns required strengthening to bear the increased loading from the new roof structure which, at approximately 48,000 square metres, and with a maximum cantilevered length of 84m, is twice the area and three times the span of the original.

The construction sequence and hence modelling and analysis requirements for the new roof took place in three distinct phases:

LUSAS was required to verify the adequacy of the global structure and structural members at critical stages of construction. This involved:

LUSAS

Forge House

66 High Street

Kingston upon Thames

Surrey

KT1 1HN

United Kingdom

We only send occasional emails. Sign-up and stay up-to-date with the latest developments in the world of LUSAS..

LUSAS online sales Dismiss