Texas Department of Transportation was retained by Fort Worth city authorities to advise on the suitability of upgrading and strengthening the existing West 7th Street Bridge to allow for wider pedestrian footways and potential future light rail traffic. When this was proved to be not the best course of action a decision was made to replace the structure with a new precast network arch replacement – believed to be the world’s first of its kind.

TxDOT chose to use LUSAS Bridge analysis software to assist with its design of the new bridge and investigate and analyse numerous post-tensioning layouts for a variety of construction stages in order to optimise the post-tensioning required.

Client: Fort Worth city authorities

Structural engineer: Texas Department of Transportation

In LUSAS, 3D thick beam elements modelled the arch rib and tie and 3D bars represented the hangers. Thick shell elements modelled the knuckle joints, with this modelling methodology being verified using a 3D solid model of the knuckle joint. The main aim of the analysis was to keep the arch concrete free of tension for durability, aesthetics and to maintain consistency in the analytical assumption of uncracked sections. Due to the connection details and slenderness of the hangers, any LUSAS model that produced compression in the hangers was deemed unsuitable and a modified configuration was evaluated.

Arch modelling methodology

Construction sequence modelling for a single span.

First eigenmode obtained from a three lane loading assessment.

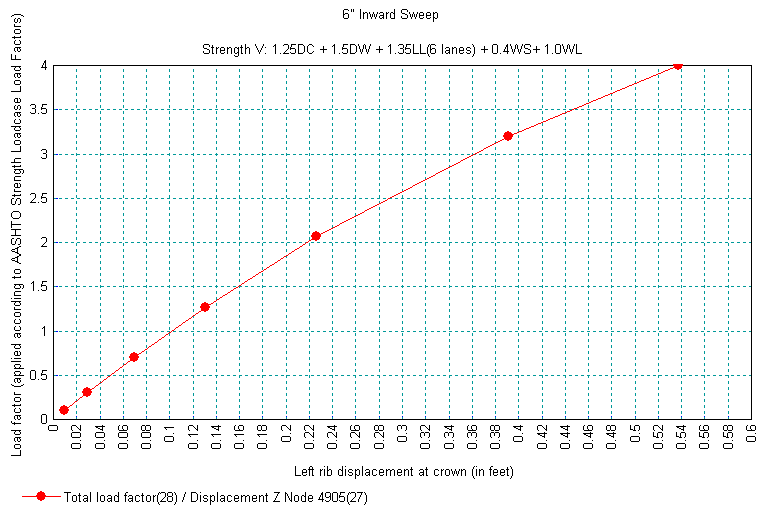

Load / Displacement graph for the crown of the arch.

Eigen buckling studies were undertaken for initial stability analysis of the completed structure. The lowest Eigen buckling value of 13.3 was found to occur for the Service I load combination comprising six lanes of traffic and wind load. The resulting arch buckling mode showed a maximum deformation at the arch crowns in the direction of the wind loading. A more rigorous nonlinear buckling analysis was also performed and, for this, seven different factored loadings from AASHTO LRFD Bridge Design Specification Load Combinations I, III and V were examined. The LUSAS model revealed that, even for the most severe condition, Strength III (transverse wind), the crown deflection at a load factor of two was only 2” (50mm) and the load-displacement curve was nearly linear.

A further LUSAS study was undertaken to investigate the negative consequences of initial out-of-straightness of the arch in the lateral direction that might arise from improper casting, improper storage, variation in modulus of elasticity due to bleed water migration during the horizontal casting, or some other unknown cause. To generate the most severe initial out-of-straightness arch profile, an Eigen analysis was carried out using the load factors for the Strength V load combination with six lanes loaded. The displaced profile was then used in a nonlinear analysis with the same loading applied and with the initial out-of-straightness profile scaled so that the crown lateral displacement was 6” (150mm). Even with this drastic initial out-of-straightness of the arch in the lateral direction, the additional crown deflection was only 2 ¾” (108mm) at a load factor of two, and the load-displacement curve still had not levelled out.

Dean Van Landuyt, Project Manager, Texas Department of Transportation

LUSAS

Forge House

66 High Street

Kingston upon Thames

Surrey

KT1 1HN

United Kingdom

We only send occasional emails. Sign-up and stay up-to-date with the latest developments in the world of LUSAS..

LUSAS online sales Dismiss